HF氟化氢刻蚀

HF气相刻蚀是一种强大的微电子制造刻蚀技术。使用HF气体进行氧化硅刻蚀,氧化硅表面与HF反应,生成SiF4分子。

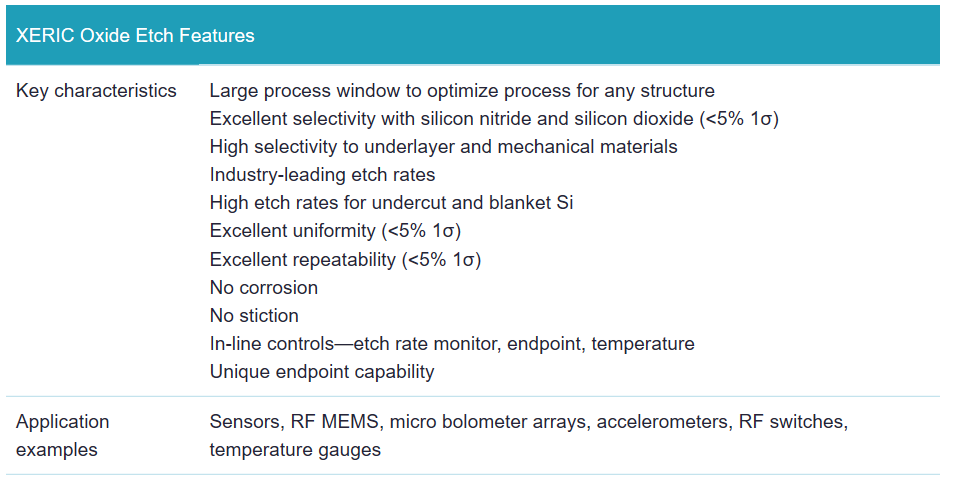

To create a MEMS microstructure, a release etch process is required in order to remove the structural material and leave the mechanical structure with clean and free surfaces. It is essential that removal (etching) of the sacrificial material does not damage or restrict the operation of the MEMS device. To ensure full performance and reliability, the remaining mechanical structure needs to be free from residues, particles and damage, and prepared for the application of an anti-stiction coating or packaging process steps. XERIC™ vapor HF (Hydrogen Fluoride) etching—or vapor phase—sacrificial release etching from memsstar offers many benefits to companies engaged in MEMS development and manufacturing.

设备用途

这种工艺主要用来对氧化硅的同向性刻蚀。这种刻蚀工艺是完全干燥的,去除了传统湿法刻蚀过程中的粘附问题。对于释放过程中容易粘附的结构,比如mems麦克风,加速度计等产品非常适用。

Using memsstar’s XERIC dry anhydrous HF etching is unique because it eliminates stiction in a single process. The patented process is compatible with the widest wide range of metals—especially Al/alloy and other metals commonly used in MEMS mirrors and electrical contacts.

Sacrificial Oxides:

Thermal oxide, TEOS, SOI bonded oxide, quartz, PECVD oxide, spin-on oxide, low-temperature spin-on glass

Protective Layers:

Aluminum, silicon carbide, Si-rich LPCVD nitride, stoichiometric PECVD nitride

Metal Layers:

Gold, copper, TiW, nickel, aluminum, Ti, TiO2

系统构成

由控制系统、真空系统、工艺腔室、工艺气体配送管路和控制系统、电源控制系统等部件组成,系统满足使用牺牲层刻蚀工艺释放牺牲层材料氧化硅的需要。

技术指标

1. 释放良率,无黏附的干法释放,Mems结构100%完全释放

2. 刻蚀速率,悬臂结构大于1um/min;空白暴露氧化硅大于0.1um/min

3. 片内均匀性≤5% 1s

4. 片间均匀性≤5% 1s

5. 选择比:对PECVD氮化硅>30:1